Elevators Market

News, Technical, Event, Spart Part Of Elevators And Escalator

News, Technical, Event, Spart Part Of Elevators And Escalator

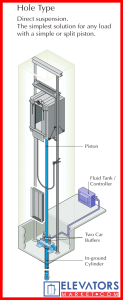

A third major type of elevator in use today is a modern version of the hydraulic elevator. Most hydraulics are direct-plunger-driven from below (the cylinder extending into the ground as high as the elevator rises), and the operating fluid is oil moved by high- speed pumps rather than water under pressure see the figure bellow:

Hydraulic_passenger_elevator_direct_plunger

Rapidly gaining favor are roped or indirect hydraulic elevators as well as many “holeless” types, some utilizing telescoping pistons. Hydraulic elevators today are used for both passenger and freight service in buildings from two to six stories high and for speeds from 25 to 200 fpm (0.125 to 1.0 mps). Single-ram capacities will range from 2000 to 20,000 lb (1000 to 10,000 kg) or more. Multiple rams are used for high capacities of 20,000 to 100,000 lb (10,000 to 50,000 kg). Varied speeds and high capacities are obtained through multiple pumps. Elevatoring performance time considerations of hydraulic elevators are slightly slower than those for geared elevators.

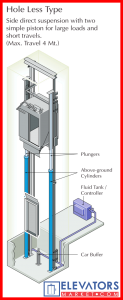

Drilling a hole for a direct-plunger hydraulic elevator has always been of concern, since underground conditions are often unknown. This concern has led to a number of equipment variations, namely, the “holeless” hydraulic and the indirect drive (roped) hydraulic. The former, shown in Figure bellow:

Is favored for the lower rise; the plunger (also called a jack or a ram) is mounted on the side of the car and connected to the top of the car structure. A variation is the use of a telescoping plunger , which allows extended travel. Heavier cars can be accommodated by two plungers, one on each side of the car.

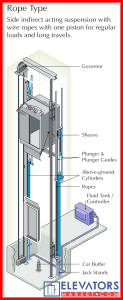

The indirect hydraulic (currently termed “roped hydraulic”) consists of an underslung roping arrangement, with the ropes driven by a vertically traveling sheave mounted on a jack located at the side of the car.

This is a 1-to-2 roping arrangement, since 1 ft of plunger travel allows 2 ft of car travel. As with any suspended elevators, an elevator code requirement is to provide a safety device to prevent falling if the hoisting rope fails.

A growing concern regarding direct-plunger hydraulic elevators is the condition of the cylinder after being buried in the ground for a number of years. Earlier units had a minimum of external protection, whereas those installed recently are usually encased in PVC or other anticorrosion material. Any loss of oil in the pump unit must be thoroughly investigated, and an underground leak correction often involves total replacement.